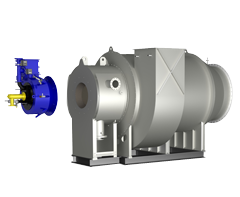

Hot gas generators for low-temperature applications

CCS-LT

Capacity range

Fuels

Applications

The main points

- Outlet temperature 400 °C to 650 °C

- Fast control response

- Short startup and shut-down times

- Very homogeneous temperature profile at the outlet

- Low weight and small dimensions

- Low pressure loss allows for economical fans

Fast control response and homogeneous temperature profile

Combustion chambers with refractory brickwork reach their limits as soon as increased heat flow requirements are placed on the downstream process (for example in intermittent operation, if the temperature changes quickly or with short startup and shut-down times). SAACKE offers a series of proven and cost-effective solutions with various designs of all-steel combustion chambers. Because of the low pressure loss on the mixed gas side, the CCS-LT combustion chamber series is ideal for large volume flows of mixed gas and therefore permits low hot gas outlet temperatures.

All-steel combustion chambers consist essentially of a double-walled steel casing, a burner mounted on the front wall and a mixing system at the outlet for hot gases. The furnace is not brick lined, which means the design can be considerably lighter. It is delivered to the installation site completely mounted. This low weight is a special advantage that facilitates very fast startup and shut-down for the combustion chamber as well as rapid temperature changes in operation.

Steel combustion chambers can also be lined with ceramic fiber mats. These variants generally provide a higher temperature level and reach outlet temperatures of up to 900°C. This design principle is also used in a special version for GCUs (gas combustion units) on LNG tankers. In this design, capacities of up to 90 MW are possible.

An SSB series burner forms the core of the combustion system: Its gas or oil flame is not only very stable, but also extremely short. Yet the outer dimensions of the hot gas generator are still compact and can be mounted in the plant in any installation position.

The mixed gas enters the double shell tangentially, cools the furnace and is mixed evenly with the hot gases emerging from the nozzles at the furnace end. The temperature profile is especially balanced at this point and is extraordinarily homogeneous with +/- 20°C across the entire window. Pressure loss is extremely low overall, thus allowing for large volume flows, very low outlet temperatures and economical mixed gas fans.

The all-steel combustion chamber of the CCS-LT series are all based on proven standard products and can be adapted or expanded as requested by customers. In this way, optimum manufacturing quality and expert engineering facilitate solutions to especially challenging requirements.