SSB

Capacity range

Fuels

Applications

The main points

- Sturdy design adapted to process combustion systems

- Unmatched stable and short flame

- Low emissions, even under difficult conditions

- Ideal as a startup and support burner

- Suitable for sub- and superstoichiometric combustion with lambda 0.3 – 4

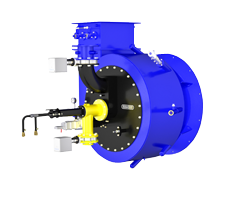

Short flame for process combustion systems

If furnaces are limited in the high load range, it’s time for the SSB swirl burner series. It is based on SAACKE steam pressure atomizers, to which a tangential windbox has been added. This causes the combustion air to be intensively swirled and allows for an especially short and stable flame.

The swirl can be finely adjusted with a swirl slide in the burner, so that the length of the flame can be specifically adapted to local conditions. For example, with a flame length of only 3 meters and capacity of 30 MW, the air guiding produces outstanding results mixing the fuel so that temperature peaks and thermal NOx are also effectively prevented.

Gas and oil are directed into the furnace with a fuel gun. This makes firing especially flexible because the burner can be changed over to other fuels within a very short time. Great flexibility is a trademark of the SSB series: It also allows for firing using gases with low heat values or low-calorific liquids in a special design – without an expensive support fuel.

Regardless of the fuel, all basic variants already have the equipment features that are needed for hard operation in process combustion systems. That includes for example a solid built-in heat protection shield that protects the entire burner from heat radiated back out of the furnace. Also included is a gun retract mechanism that reliably prevents oil from cracking in the fuel gun. The modular design of the burner makes additions or conversions easy. With a second fuel gun, firing with two liquids, two gases and a pulverized fuel is even possible.

With all these details, the SSB is still an especially robust and reliable component for operating combustion chambers, waste incineration plants or special solutions based on thermal process. Although it is highly insensitive, not a single gram of fuel goes unused. The burner also features low emission values and extremely stable flame.

The high energy efficiency and low maintenance cost represent the results of decades of continuous development work.

With all its flexibility, the SSB is uncompromising in just two attributes: high quality and extremely long service life.